Customer: Sondes Place

Location: Surrey

Project Type: Luxury refurbished property project

Services Used: CAD draftsmen, estimators, patternmaking, joinery department and casters.

Products Delivered: Cast stone castellation copings, pier caps and entrance pillars

Cast Stone Colour: Portland

Background/ Challenge

Sondes Place is a luxury property project in Surrey that needed a unique refurbishment. The developer approached our Senior Estimator, Gavin, having worked with him on numerous other projects. This refurbishment property was unique as it required bespoke copings for a castellated wall, which isn’t something that you see every day!

The customer also wished to create an impressive entrance by having bespoke pier caps that would be in keeping with the copings, plus cladding for the pillars. One of the main challenges we encountered during this project was the manufacture of bespoke castellation copings, so we’ll talk about that here as well.

Approach

Design Process:

The design approach that our team utilised for the castellation copings and entrance pillars involved the use of advanced CAD software to ensure precision and accuracy in our designs. However, due to the nature of the work and the specific requirements of each element, we had to adapt and use different processes for each.

Castellation Copings: Our in-house CAD draftsman used the software to generate a detailed drawing showing the layout of the wall and the variations required for the bespoke copings. The CAD drawing allowed the team to accurately design each coping stone to precise measurements. This resulted in a perfect fit for each respective part of the castellation.

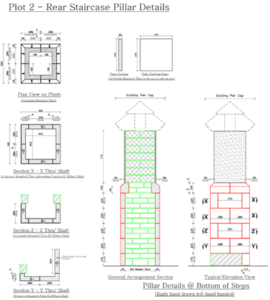

Entrance Pillars: The design process for the entrance pillars with pier caps was slightly different, as we were tasked with creating an existing brick pillar into one that was made to look like it was completely made from cast stone. Our expert team created a CAD drawing to design the bespoke panel sections to fix and fit onto the brickwork for the entrance pillars and matching coping stones and pier caps.

Bespoke Cast Stone:

All the items produced were bespoke and matched our Portland-coloured cast stone, which complements the rest of the property, as you will see in the production process below:

Production Process:

Our patternmaking and joinery department began the production process by creating bespoke moulds based on the CAD drawings. These moulds were essential for shaping the cast stone elements, including the castellation copings, pier caps and entrance pillars, to meet the specific design requirements.

Our team carefully placed the semi-dry cast stone mixture into the moulds by hand, making sure it was well compacted. This process helps us create precise and detailed bespoke cast stone pieces that are unique.

During the production of the L-shaped panels for the castellation copings, our team encountered a challenge with the curing process. Despite semi-dry cast stone not requiring overnight moulding, the thin 50mm panels needed additional curing time inside the moulds to prevent ‘slumping’. Although it wasn’t noticeable to the eye, our quality checks revealed that the sections were slightly out of line when we put a set square against them. Prompt detection of this issue allowed us to recast the affected sections without causing delays to the project timeline.

Post-Installation Support:

No support was required as the customer had experience in cast stone and was highly knowledgeable in the field. However, we usually recommend that they read our cast stone cleaning guide.

Results

The successful completion of the project was a testament to the collaborative efforts of our dedicated in-house team, effective client collaboration, and rigorous quality check process. It was a rewarding experience for our team to work on this project, particularly appreciating the striking castellated effect that was achieved. The final results truly spoke for themselves, showcasing a unique and impressive design that added a significant ‘wow factor’ to the property.

Conclusion

This project illustrates our capability in handling challenging bespoke projects thanks to our in-house resources. These include CAD draftsmen who can produce accurate drawings, a fully equipped patternmaking and joinery department for creating bespoke moulds, and, of course, our high-quality casting capabilities.

“I am incredibly pleased with the teamwork and dedication shown by the Acanthus team throughout the ‘Sondes Place’ project. The finished project is truly amazing, exceeding all expectations and highlighting the exceptional craftsmanship and attention to detail.”

Gavin – Project Manager at Acanthus

Contact Us

All our products are available in a range of natural stone shades with the same texture and feel as stone. Items we supply exceed the performance requirements of BS1217, the UKCSA Specification for cast stone, and NBS clause F22.

If you require any further information about our work or would like to get a quote on our range of bespoke or standard cast stone products, contact one of our friendly Acanthus team members or call us on 01773 540704.