Creating bespoke cast stone involves a meticulous process that combines careful planning and skilled craftsmanship at every production stage. From the initial consultation and design phases through to the hand-casting and finishing touches, each step is carried out precisely to ensure the highest quality and consistency in the final product.

In this blog, we will be discussing the process of making bespoke cast stone as well as examining the wide array of benefits of opting for cast stone products for your home or commercial project.

The Benefits of Bespoke Cast Stone

When it comes to enhancing the exterior of your home, bespoke cast stone is a fantastic option that offers a range of benefits. Here are some reasons why choosing bespoke cast stone for the exterior of your house and garden is the right route to take:

Make it Your Own

With bespoke cast stone, you have the freedom to create unique pieces that perfectly suit your taste and style. From porticos to garden products and architectural details, bespoke cast stone allows you to personalise the exterior of your home in a way that reflects your individuality.

Increased Property Value

When it comes to increasing the value of your property, choosing bespoke cast stone for your exterior can be a wise investment. According to the United Kingdom Cast Stone Association (UKSCA), cast stone can boost the value of your home by up to 5%1 .

Consistency

Achieving consistency in bespoke cast stone is achieved through our specialised mixing techniques in semi-dry products. This produces a uniform colour that is free from the natural variations and imperfections commonly found in natural stone.

Matching Existing Stonework

If you have existing stonework on your home that has been damaged or is missing pieces, bespoke cast stone can be custom-made to match the original design. Skilled craftsmen can carefully replicate the size, shape, and texture of the existing stones, ensuring a seamless blend that maintains the overall aesthetic integrity of your property.

Additionally, if you live in an area with architectural guidelines or historical preservation requirements, you can use bespoke cast stone to match the stonework of other homes.

Planning Approval

Obtaining planning approval for alterations to listed buildings, heritage sites, or properties within conservation areas can be made easier by opting for bespoke cast stone. The customisation options offered with bespoke cast stone allow for elements to be created that align with the guidelines and regulations set by planning authorities.

Non-Standard Builds and Wall Sizes

In some instances, construction may start before sourcing stonework, only to realise that standard options won’t fit non-standard builds and wall sizes. This dilemma can be frustrating and costly, as off-the-shelf solutions may not align with the unique dimensions and specifications of the structure. Bespoke cast stone offers a solution to this problem providing flexibility to create custom pieces that perfectly match the unconventional shapes and sizes of the building.

What is Cast Stone Made From?

Before we can understand how to make bespoke cast stone, it’s important to first understand what cast stone is made from. Cast stone is a versatile material made of a mixture of crushed limestone, washed sand, cement, and additives. This combination of natural materials results in a durable and aesthetically pleasing product that closely resembles natural stone.

For more information, you can read our previous blog here: https://www.acanthuscaststone.co.uk/what-is-cast-stone-made-from/

The Process of Making Bespoke Cast Stone

Making bespoke cast stone is a meticulous process that involves careful planning and attention to detail. Here is a step-by-step guide on how we would create bespoke cast stone for your project:

Call Your Estimator/ Project Manager

The process begins with a call to one of our estimators or project managers to discuss the details of your project. During this initial consultation, you can share your vision, requirements, and any specific guidelines or regulations that need to be considered. This step is crucial in ensuring that the bespoke cast stone meets your expectations and requirements.

Based on the information gathered during the initial consultation, a quotation will be provided for the bespoke cast stone. Once the quotation is approved, the order will be placed, and the production process will begin.

CAD Product Drawings

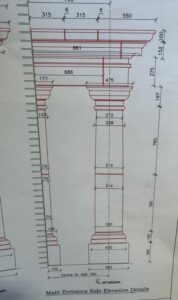

Our skilled CAD draftsmen play an important role in the custom creation process by producing detailed and precise manufacturing drawings using Computer-Aided Design (CAD) software. These drawings serve as a blueprint for crafting bespoke cast stone elements tailored to your exact specifications. Once the drawings are finalised, they are submitted for your approval, allowing you and your architect to review and provide feedback before production begins.

This is an example of a portico CAD drawing:

Drawings Transferred

Once you have approved the manufacturing drawings, the next step in the process is to transfer them to our fully equipped patternmaking and joinery department.

Here, our skilled craftsmen use traditional techniques to create the moulds necessary for producing bespoke cast stone products. This is an example of a mould:

Hand-Cast

Following the creation of the moulds in our patternmaking and joinery department, the next stage in the process involves hand-casting your bespoke items. Our skilled craftsmen carefully compact the semi-dry cast stone mixture into the moulds, ensuring that each piece is carefully produced with precision and attention to detail. Hand-casting allows for a level of artistry that mass production methods simply cannot match, resulting in unique and beautifully crafted bespoke cast stone.

Adding Colour

Adding colour to cast stone is a crucial step in the manufacturing process as it helps to create a more realistic and natural-looking finish. By incorporating colour pigments into the mix, we can achieve a wide range of hues that closely resemble those found in natural stone. This not only ensures consistency in the colour throughout the product but also provides flexibility when it comes to selecting the perfect shade for a particular project.

Curing Cast Stone Products

Ensuring the longevity and durability of cast stone products is crucial, and this is where the curing process plays a significant role. Once the cast stone has been demoulded, it is essential to allow it to cure properly to achieve the desired strength and appearance. Depending on the cast stone product and its size, the curing process typically takes at least two weeks to complete.

Quality Checks Stage

Before any products leave our premises, we have a number of quality control stages to make sure that we are 100% with the product. To ensure this, we thoroughly check our manufacturing process and follow a three-step quality control procedure. This includes the Factory Check, Order Check, and Dispatch Check to make sure that our cast stone is up to our high standards before it leaves our factory.

Why Acanthus

Choosing the right cast stone supplier for your needs can be a challenging task. At Acanthus, we understand the complexity of this decision and are here to guide you through the process. With a wide range of options available in the market, below are some of the key reasons why we stand out as the ideal supplier for your cast stone requirements.

Our Range of Cast Stone Products

Firstly, at Acanthus Cast Stone, we offer a wide range of cast stone products for your property and garden that can be tailored to your own needs with our bespoke cast stone capabilities. From Pier Caps, Window Surrounds, to Ball & Finials and Name & Date Stones, our bespoke product range is sure to have something that suits your unique style. You can explore our extensive bespoke cast stone product range here.

Our Colour Options

To make our products even more tailored to your needs, we provide a selection of colour options, as you can see Here:

If you would like to experience the look and feel of our cast stone and explore the available colours, feel free to request a free sample. By physically interacting with the stone and seeing its colours in person, you can gain a clearer vision of how it will enhance your project. The sample can even be taken to planning approval meetings if appropriate.

Quality and Durability

At Acanthus Cast Stone, we place a strong emphasis on the quality and durability of our products. Our cast stone items are available in a variety of natural stone shades, all of which boast the same texture and feel as carved stone. Our products surpass the stringent performance requirements outlined in BS1217, the UKCSA Specification for Cast Stone, and NBS clause F22.

Cost-Effective Solutions

We are committed to helping our clients keep costs to a minimum without compromising on quality. Through our experience and expertise, we can often suggest slight design tweaks that make the manufacturing process more efficient and cost-effective. By working closely with our clients and examining the details of their projects, we can identify opportunities to achieve savings while maintaining the overall design integrity. You can trust Acanthus Cast Stone to deliver high-quality, durable cast stone products that meet your needs and budget requirements.

Conclusion

In conclusion, the process of creating bespoke cast stone involves careful planning and craftsmanship at every stage. From initial consultation to design, production, and hand-casting, each step is carried out precisely to ensure quality and consistency.

“At Acanthus Cast Stone Products, we take pride in offering an extensive selection of bespoke cast stone products that are designed to complement any style and budget. Our versatile range of products is suitable for a wide range of homes and commercial projects, catering to diverse design preferences and requirements.”

Gavin, Project Manager at Acanthus

For further information on our bespoke cast stone products or to request a quote, feel free to contact one of our friendly Acanthus team or call us on 01773 447065.