Bespoke cast stone has long been a popular choice in architecture, allowing homeowners, builders and architects to go beyond standard designs and create something truly individual. It’s about tailoring the details, from the size to the shape, so that each piece complements your project perfectly. At Acanthus, we know just how important this is, with around 30 – 40% of the products we make being bespoke.

In this ultimate guide to bespoke cast stone, we will explore the benefits of choosing bespoke cast stone, such as adding value to your property and matching existing stonework.

Additionally, we will provide insights into the process of creating bespoke cast stone, from the initial consultation to manufacturing and quality checks. Real-world examples from our portfolio will showcase the craftsmanship behind our bespoke projects.

The Benefits of Bespoke Cast Stone

There are many benefits of opting for bespoke cast stone. Here are just a few examples:

Adding Value

If you’re looking to add value to your home, bespoke cast stone products can be a fantastic choice. The United Kingdom Cast Stone Association (UKSCA) notes that incorporating bespoke cast stone products can increase your property’s value by up to 5%1.

For more information, please read our blog on how cast stone can add value to your property.

Aesthetically Stunning Designs

Bespoke cast stone offers the opportunity to create visually stunning designs that stand out for many reasons. Customising architectural elements allows you to make them truly yours, adding your style to your project. From elegant window surrounds and grand entrances to decorative cornices, bespoke cast stone gives you the freedom to add detail that elevates your design. Because each piece is made to order, you’re not restricted by standard shapes or dimensions, meaning you can achieve symmetry, balance, or intricate detailing that might not be possible with off-the-shelf products. The result is a finish that not only enhances the beauty of your property but also creates a lasting impression.

When Standard isn’t Suitable

When it comes to building projects, sometimes standard cast stone simply isn’t sufficient. Whether it’s non-standard brickwork, stone structures, or reclaimed bricks, there are situations where a standard, off-the-shelf product just won’t do. That’s where bespoke cast stone becomes valuable.

With bespoke cast stone, you can customise the size, shape, and design to suit your specific project needs. This ensures that your finished result is practical and looks great.

Match Existing Stonework

Bespoke cast stone provides the flexibility to match existing stonework, ensuring that new features integrate smoothly with the original design. Whether you are adding new elements or replacement pieces, bespoke cast stone can be customised to match the style of your current stonework.

Beyond matching existing stonework, bespoke cast stone can also be used to repair missing or damaged stone. By creating custom pieces to fill gaps or replace broken stone, you can restore the visual appearance. Charing Cross Station is an example of this: we were asked to replace and replicate stonework on a pillar after a lorry reversed and caused damage (more on this later on).

Unique Design Features

Architects may create amazing and unique designs that demand a tailored approach. Standard, off-the-shelf cast stone may fail to perfectly fit these designs, making bespoke cast stone the best option for realising these unique projects.

Oversights

Similarly, oversights can be a common part of the design and building process. When these occur, bespoke cast stone can solve the issue. We can work with you to create custom cast stone solutions that fit perfectly with your project needs.

Process of Making Bespoke Cast Stone

Now that we understand why bespoke cast stone is ideal for your project, it is also useful to know how bespoke cast stone is made here at Acanthus.

1. Initial Consultation

The bespoke cast stone process starts with an initial consultation with one of our estimators or project managers. This allows you to outline your project vision, requirements, and any relevant guidelines or regulations.

2. Quotation and Order Placement

Following the initial consultation, a quotation for the bespoke cast stone is provided. Upon approval, the order is placed, marking the start of the production process.

3. CAD Product Drawings

Our skilled CAD draftsmen then produce detailed drawings using Computer-Aided Design (CAD) software. These blueprints for crafting bespoke cast stone elements are tailored precisely to your needs.

4. Manufacturing Process

Approved drawings are transferred to our patternmaking and joinery department, where our skilled craftsmen use traditional techniques to create the moulds needed for the bespoke cast stone products.

5. Hand-Casting

Hand-casting involves carefully compacting the semi-dry cast stone mixture into the moulds. This process ensures precision and attention to detail, resulting in uniquely crafted bespoke cast stone pieces.

6. Adding Colour

The addition of colour is a vital step in the process, providing a realistic and natural finish to the cast stone. By incorporating colour pigments, a wide range of hues resembling natural stone can be achieved, offering flexibility in selecting the perfect shade for your project. Here at Acanthus, we have a range of 8 distinctive natural stone colours you can choose from, so they can perfectly complement any building. Get your free samples here to make the best colour choices for your project.

7. Curing Process: Ensuring Durability

Proper curing is essential for the longevity and durability of the cast stone products. Once demoulded, the cast stone undergoes a curing process to achieve the desired strength and appearance, typically taking around two weeks.

8. Quality Checks: Ensuring High Standards

Before leaving the premises, thorough quality checks are undertaken at multiple stages of the process. Our three-step quality control procedure includes Factory Check, Order Check, and Dispatch Check to uphold the high standards of our bespoke cast stone products.

Read our full blog about how bespoke cast stone products are made.

Examples from Our Portfolio of Bespoke Products

Charing Cross Station

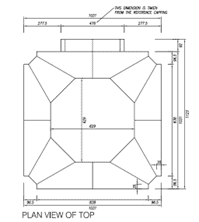

We were approached by a historic building repair and restoration firm after a lorry reversed into a pillar at Charing Cross Station in London, damaging one of the iconic pier caps. Due to the building’s historic status, any replacement stonework needed to be an exact match to the existing piers (an example of a benefit of bespoke cast stone!).

With this project, we were supplied with full CAD drawings for the replacement pier cap and cladding sections. This meant we could bypass our CAD team and issue the drawings directly to our joinery department. Our team of skilled joiners were able to create the mould to a very high standard, allowing for a beautiful cast.

The challenge of this project was the size of the cap; it measured over a metre square and weighed a staggering 480kg. At this weight, the cap could only be mechanically lifted and stripping the mould was a complex procedure.

The finished project blends in perfectly with the rest of the stonework and the station that is now structurally sound. You can see it here:

We loved working on such a famous building. If you ever pass the station, take a look and see if you can spot our new one!

Coronation Villa

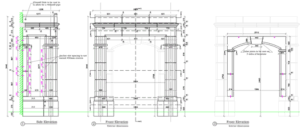

This new build project required two bespoke features. The homeowner wanted the window surrounds visible both internally and externally. This required a deeper stone section; normally, surrounds are only built into the outer course of bricks. Traditionally, stonework like this would be a single solid piece, but that can cause cold bridging, as cold can travel through the stone from outside, leading to condensation and damp issues inside the house. The modern approach is to leave a gap between the stones to prevent thermal bridging.

Our customer also wanted an enclosed, contemporary-style porch instead of the traditional portico designs supported by columns. The 2m long arched head had to be cast in one piece to avoid needing a supporting lintel (which would have been visible and spoil the look). The architect did a great job designing the porch. We then took his design and broke it into suitable pieces for casting and installation. We believe the finished product is fabulous.

You can see the CAD portico drawings related to the project here:

The customer finished off his build with our standard copings on the gable ends, door surrounds and pier caps for his entrance way, all in the matching stone colour.

Nirvana Spa

We had the pleasure of working on a luxury bespoke project with Nirvana Spa, a leisure facility in Sindlesham, Wokingham. We secured the project through a competitive tender process.

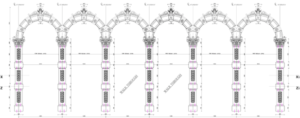

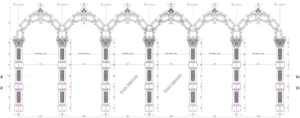

The project process was somewhat different as it involved the expansion of their existing facility. Therefore, we had to replicate an existing design (another benefit of using bespoke cast stone!). We achieved this by taking photos of the existing design, which we uploaded onto our CAD software.

We then created bespoke cornices, window surrounds, and internal arch façades in Bathstone cast stone.

The finished result (see below) speaks volumes and creates a luxurious feel for the spa.

For more information, you can read the full case study here: https://www.acanthuscaststone.co.uk/luxury-bespoke-nirvana-spa-leisure-facility-project/

The Pentagon

Another example of our bespoke cast stonework involved working with YG Construction on their new build project ‘The Pentagon’. They are a well-known luxury developer in London and achieved substantial recognition by winning the prestigious Housebuilder Awards 2017.

YG Construction designed a beautiful luxury home, and it was a pleasure to be chosen to supply all the cast stone elements. Not a company to settle for the ‘norm’, they required numerous bespoke features for the build. Their architects provided us with excellent detail, but we also had to find a solution where two different cornice profiles merged. Rather than an ugly transition at these points, we developed designs that allowed the two profiles to blend seamlessly.

This house has an undeniable wow-factor, and everyone was thrilled at the finished result.

Sondes Places

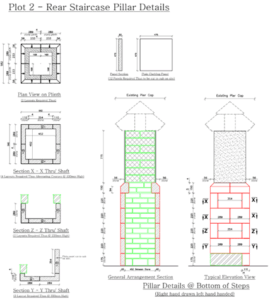

The contractor approached our Senior Estimator, Gavin, having worked with him on other projects. This refurbishment property was quite unique as it required copings for a castellated wall, not something you see every day! The customer also wished to create an impressive entrance by having bespoke pier caps that would be in-keeping with the copings, plus cladding for the pillars.

Often, we supply full-length coping stones for the contractors to cut them to the correct sizes, but in this instance, we made the copings to exact measurements, allowing each stone to fit the corresponding part of the castellation perfectly. Due to the layout of the wall, there were many variations required, as seen on the drawing below.

For the entrance pillars, we had the challenge of turning a brick-built pillar into one that looks like it’s made from cast stone. We supplied panel sections that could be fixed onto the existing brick pillar, giving the impression that they are solid stone.

Although semi-dry cast stone does not need to be left in moulds overnight, we found that we had to leave the L-shape panels to cure inside the mould. This was down to them being only 50mm thick; the items were ‘slumping’ slightly after being stripped from the mould. It wasn’t noticeable to the eye, but when you put a set square against them, it was out of line. Luckily, our rigorous quality checks detected this, and we were able to recast the sections without delaying the build.

We really enjoyed working on this project and love the castellated effect.

You can view our full project portfolio here.

How to Choose a Cast Stone Supplier

Choosing a reliable cast stone supplier is crucial for the success of your project. From the quality of products to customer service, several factors need to be considered when making this important decision. Here are just some of the ways to decide on a cast stone supplier:

Reviews

When searching for a cast stone supplier, it’s important to take the time to read through reviews from previous customers. These reviews can provide valuable information about the quality of the products, customer service, and overall experience with the supplier.

One of the best ways to access reviews is by visiting popular review sites such as Google reviews. Here, you can find a wide range of opinions from customers who have worked with the supplier in the past. Pay attention to the overall rating, as well as specific comments about the products and services offered, and how the reviews are replied to by the company.

Colour Options

Having a variety of colour options is also essential when looking for a cast stone supplier, as this can significantly impact how well your cast stone blends with its surroundings or stands out to add that curb appeal to your project. To help you make the best choice, we have created a practical guide here.

Here are our colour options:

Design Considerations

When choosing a supplier, it’s important to consider the range of standard products they offer. A good supplier will provide a variety of designs in different styles, sizes, and functionalities to meet your specific requirements. We will always offer standard products where possible, if that means you can find the right design for your project at a lower cost. So, having a comprehensive range of standard products ensures that you have plenty of options to choose from.

Accreditations

Accreditations play an important role in ensuring the quality and durability of cast stone products. We take pride in the fact that the items we supply are fully frost-proof and go beyond the performance requirements outlined in key industry standards such as BS1217, the UKCSA Specification for Cast Stone, and NBS clause F22.

Lead Times

Ensuring that your cast stone provider can meet delivery deadlines is essential for keeping your project on schedule. Delays can disrupt the workflow and cause headaches for contractors, so it’s important to choose a supplier with a proven track record of timely deliveries.

Conclusion

In conclusion, bespoke cast stone offers a range of benefits for architectural projects, such as increased property value. The process of creating bespoke cast stone involves skilled craftsmanship and attention to detail. Real-world examples from our portfolio demonstrate the stunning results that bespoke cast stone can achieve. By choosing a reliable supplier with colour options, design considerations, accreditations, and prompt delivery times, you can ensure the success of your project.

“At Acanthus Cast Stone, we understand the need for bespoke projects and how it can truly make your project unique. That’s why we offer a full range of bespoke cast stone product types.”

Gavin, Project Manager at Acanthus

For further information on our bespoke cast stone products or to request a quote, feel free to contact one of our friendly Acanthus team members or call us on 01773 447065.