Luxury bespoke ‘Cheyne Place London’ residential project

(Before and after images courtesy of Google Maps)

Customer: GPF Lewis – a long-standing customer since 2018.

Location: Cheyne Place, London, SW3.

Project Type: Residential – Luxury Apartments.

Services Used: CAD draftsmen, estimators, project managers and of course our joinery department.

Products Delivered: Bay Window Surrounds, Coping Stones, Panel Façade, and C-Section Columns.

Overall Project Price: £50k

Background / Challenge:

Since 2018, we have established a strong and enduring partnership with GPF Lewis, collaborating on multiple projects together. GPF Lewis is recognised as a reputable and accomplished specialist in construction, refurbishment, and maintenance across various sectors.

This residential project presented several challenges that required meticulous planning and execution. The large flat panels, although appearing straightforward, required precise coordination between all the services used with the site to ensure alignment of the fixing points.

In addition, extra reinforcement and lifting points were needed for logistical purposes, and the bespoke moulds had more timber supports to avoid “bowing” under the weight of the panels. These stones were carefully checked for “squareness” upon completion. Other tricky aspects needing careful consideration included the column stones to ensure sufficient cladding of the steelwork.

Approach:

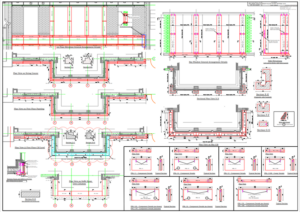

- Design Process: The architect supplied the general arrangement drawings for the renovation and extension (see below) which were helpful. Gavin, our project manager, jointed the stone up into manageable sections, taking note of the fixing points to allow correct alignment.

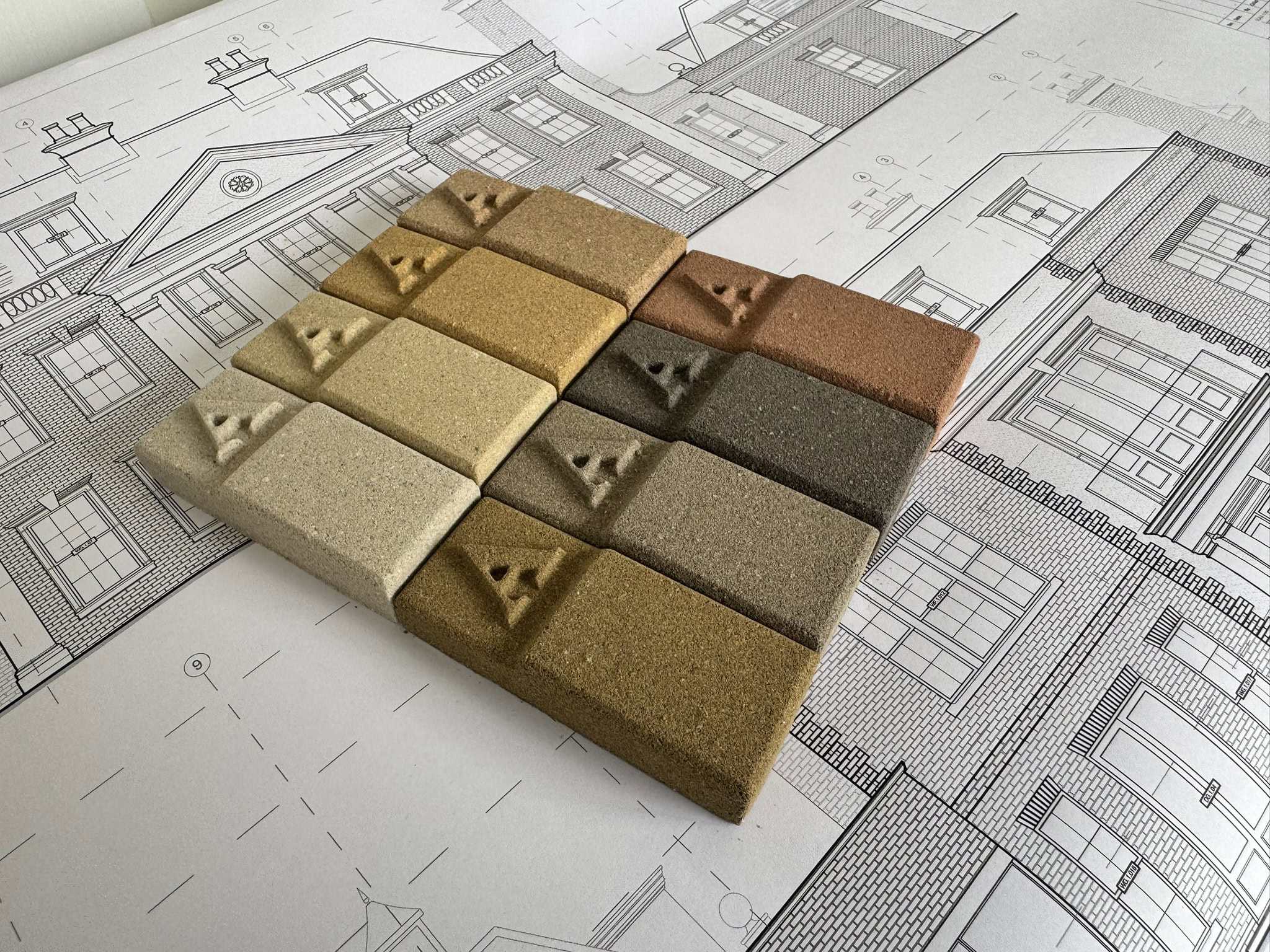

- Bespoke Cast Stone: The use of bespoke cast stone is one of the services we offer. With bespoke moulds, we can fully customise the production process, ensuring that each product is tailored to match existing features or suit specific architectural drawings. Our skilled CAD draftsmen worked closely with our client to produce accurate drawings for the project, providing a clear visualisation of the result. These drawings were then submitted for customer approval. Feedback from the client allowed us to incorporate their desired modifications before we proceeded with production.

- Production Process: A higher level of quality control was required due to the bespoke nature of the project. Gavin worked closely with our casters to ensure the necessary lifting socket and reinforcement locations were adhered to, clearly an important part of the process to ensure the final products could be installed efficiently and were fit for purpose.

- Installation Recommendations Provided: We discussed fixing options with the customer and agreed on suitable rebates that were cast within the stone to allow for fixings. Gavin and the casters expertise helped ensure that the fixing options would work at the point of installation.

Here’s a photo of the renovation and extension in progress (Courtesy of Google Maps):

- Post-Installation Support: No support was required as the long-standing customer had experience in cast stone and is highly knowledgeable in the field. However, we would usually recommend that they read our cast stone cleaning guide, and use the stone sealer Lithofin to keep the lovely light stone looking good.

Results:

Overall, our team’s commitment to meticulous planning, problem-solving, and collaboration with GPF Lewis were crucial in overcoming the challenges and delivering a successful outcome for this residential project.

Below is a recent photo taken from Google Maps. Look how amazing the property looks, dare we say, compared to its neighbours:

Conclusion:

The GPF Lewis residential project in Cheyne Place, London displayed our ability to confront challenges and deliver exceptional results. Our team of CAD draftsmen, estimators, project managers, and our in-house joinery department worked seamlessly to overcome the unique obstacles presented by this luxury apartment renovation and extension.

Using our bespoke products proved crucial to the project’s success. Crafted Bay Window Surrounds, Coping Stones, Panel Façade, and C-Section Columns elevated the quality of our work.

Coordination between our various departments, use of additional reinforcements, and careful consideration of fixing points were all important. Working closely with the architect, we developed a meticulous design to ensure alignment with the steelwork. Using our tried and tested production techniques as well as unique quality control procedure, we ensured that every stone section delivered to site was of a high quality, dimensionally correct and worked seamlessly with the other stone sections.

The end result speaks volumes. The use of Portland cast stone ensures it blends into the surroundings as this stone colour is used across London. It provides a modern and sleek appearance to these luxury apartments. Clearly, if you are looking to renovate your apartments in London, this stone must be one to consider, and perhaps the buildings in close proximity are now somewhat envious of their neighbour.

‘‘Throughout the course of this project, we confronted numerous challenges head-on. We love a good challenge! We thrive on turning them into opportunities for growth and creativity. One of the key factors that contributed to our success in overcoming the obstacles was the use of our bespoke products combined with great team work.’’

Gavin – Project Manager at Acanthus

Contact Us

A significant part of our business involves catering to the specific needs of cast stone projects. Bespoke products are often required to match existing features or adhere to architectural drawings, whether for commercial, residential, or private projects.

If you are interested in our bespoke cast stone products, please do not hesitate to contact our friendly team here.